|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

D. How does CarBuilder produce a long

lasting repair? |

| |

| |

|

|

|

|

|

|

|

|

|

|

D. 1-Practices |

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

Welds are total, not spot welds. Hammer welding is

used for repairs to panels. This is a skilled hand process to do

metalworking to shrink and forge as welds are done.

|

| |

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

Repair the original parts. Metal work skills and

fabrication reshape damaged surfaces back to like new. Solid original

sheet metal parts are almost always better to repair than replace.

(Most reproduction parts do not fit correctly and take significant

rework to make them right.) |

| |

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

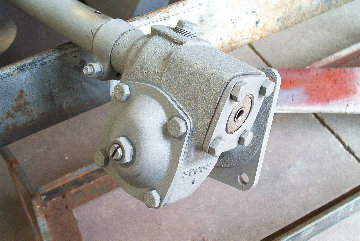

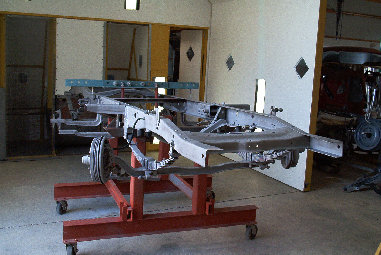

Fabrication capability is essential to make improvements. Stainless

steel brake, fuel and vacuum lines are handmade. Sheetmetal working

tools include shears, brakes, stretcher/shrinkers, rolls, Pullmax

machine and hand tools, Lathes, Mills, drill presses, plasma cutting

CNC table, MIG, stick, and Acetylene welders, and powerful 3D CAD

Engineering Computer Systems is part of the versatile Fabrication

capability. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

Block

sanded panels by hand are straight and edges are the correct radii, or

sharpness. Machine sanders are rarely used as body filler is not

required to cover large areas. Cured epoxy is block sanded by hand to

perfection without spray able (2k urethane) body fillers. Appropriate

top finishes may be acrylic enamel, catalyzed acrylic enamel, acrylic

or nitrocellulose Lacquer, urethane, acrylic urethane, polyurethane,

alkyd enamel or epoxy. Applications for durability or specific

appearance of a part or vehicle cause the selection of paint material

from about ten different chemistries of paint. HVLP and older

technology equipment is maintained to apply the wide range of materials

in a custom built paint facility. Half of these paint materials are

rarely if ever used by commercial insurance repair body shops.

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

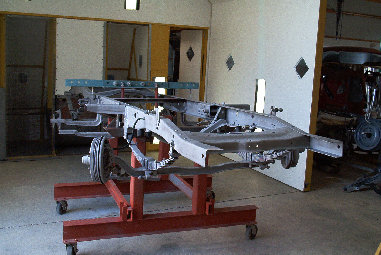

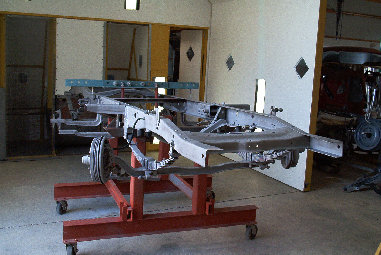

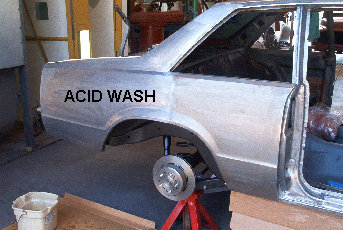

Outstanding work is made possible because cleverly

designed tools are built to hold the body or chassis or large item in a

good position to do the required task. Paint booth, cranes, dollys, and

rotisserie were designed by the owner, an inventive engineer that has

degrees in Mechanical and Industrial Engineering. |

| |

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

Organization of the project is planned to identify the work that will

be done. A proven sequence of work is followed that ensures that

quality results are repeated. A project is steam cleaned and pressure

washed when it comes in. An organized disassembly identifies and

evaluates which parts are repairable or must be replaced. Batches of

similar process jobs are organized for sandblasting and refinishing,

repairs, or other activities such as replating or reupholstering.

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

D. 2-Materials |

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

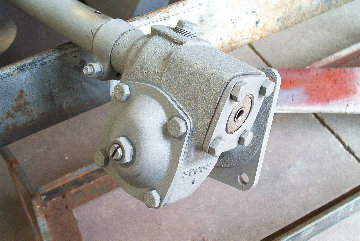

Only

epoxy primers and trace amount, if any, of glass reinforced fiberglass

mold construction filler is used. The epoxy paints are applied only to

sandblasted prepared parts, not ever over old finishes or rust. The

usual body shop quality is urethane primers slathered with easy sanding

body filler and more spray able fillers which are sanded to the correct

shape. Easy to sand is easy to chip or scrape, and whatever the finish

is, it will chip with it. In time the body filler shrinks and looses

its surface shape to become an appearance defect such as a slight oval

depression. That defect cannot happen for epoxy that is fully cured

before it is sanded. Finish paint can retain outstanding appearance for

many years without shrinkage defects when done by carbuilder

restoration methods. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

Rust is

gone before tough epoxy finish is applied to seal out moisture. The

reason epoxy is superior for rust is because it is applied and it cures

without large amounts of evaporating solvents like any other possible

choice does. The epoxy will "wet" to the bottom of the tiniest pit in

the metal and seal over with the pit full of epoxy. Any other primer

may look the same when applied but it changes in time when the solvents

evaporate. The other primers leave an air bubble in the pit or they

crack as they shrink and the tiny pit gets a tiny crack opening. Air in

the pit or through that tiny crack is the trouble. That tiny air pocket

later starts the microscopic rust spot that shows up in the future. The

bubble is not able to produce enough pressure when heated to break out,

but the moisture in all air is enough to start rust. Body filler also

absorbs moisture and will foster rust if any rust is underneath or any

cracks allow moisture in. Epoxy does not absorb moisture and does not

get brittle and crack.

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

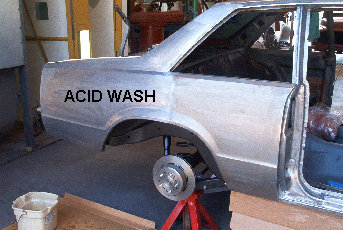

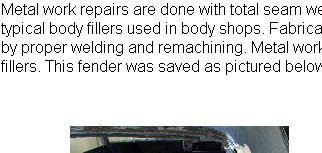

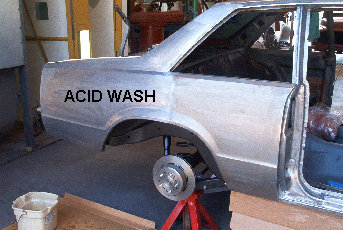

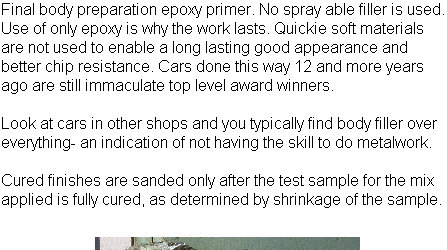

The rust in this picture forms under the paint

from a paint failure- factory applied finish- and it is called spider

rust for its shape. If this is sanded and then painted over, it will

come back again. You see cars all the time that re-rust months after

they get new paint from defects like this. Cleaning out all traces of

the rust with phosphoric acid and then sealing the metal with epoxy

primer is the only cure I have found that works for the long term. Few

other shops use acid wash because of the skill required.

|

| |

| |

|

|

|

|

|

|

|

|

E. CarBuilder Restoration

|

| |

| |

|

|

|

|

|

|

|

|

|

|

|

A total CarBuilder Restoration is high quality and

results in a car of excellent performance and pristine appearance. What

we do to create a restored car is a specialty art, because we have

engineered the equipment and have invented the skills for how to

complete a lasting, professionally restored car. |

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pictured here in TN while driven by owner on 2000

mile tour from Michigan in 2005 |

| |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright 2008 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GO BACK TO PREVIOUS PAGE |

| |